Infin8 Surfacing has been experimenting with different designs and purposes of wall cladding. Creative wall cladding can be implemented with both solid surfacing and compact high-pressure laminates.

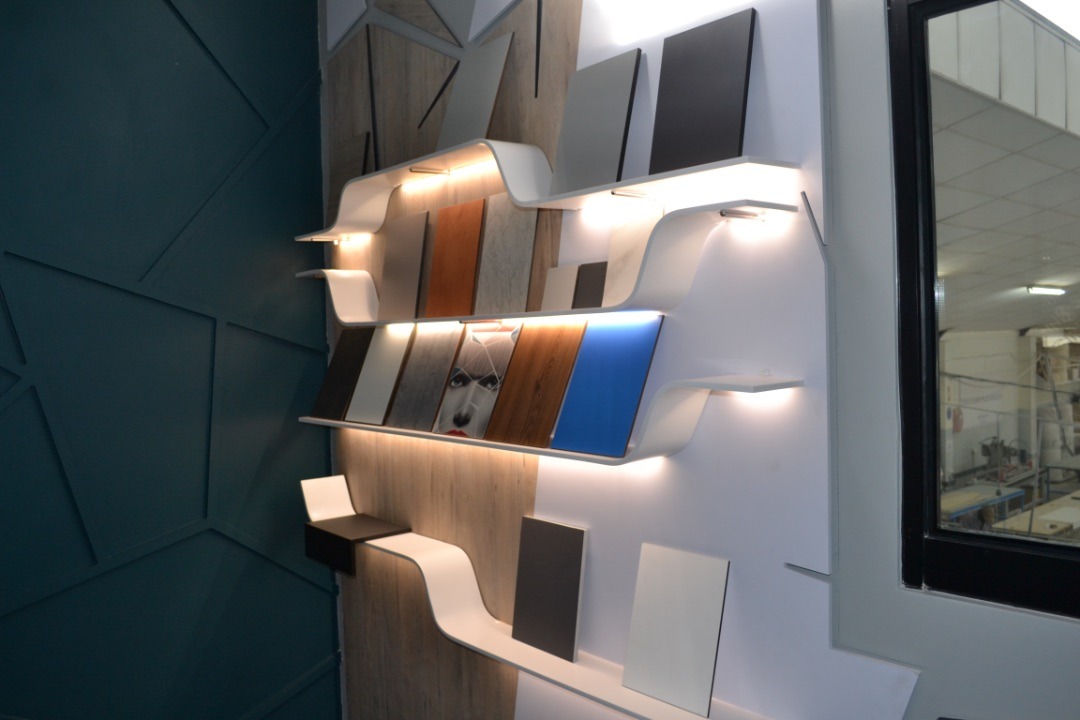

CHPL Sample Storage Cladding

Since the launch of Infin8 Compact in the middle of 2020, the material has definitely demonstrated its high-quality characteristics. Infin8 Surfacing created a structure in our boardroom to effectively display the range of finishes that compact high-pressure laminates can offer our clients. It also gave us the opportunity to showcase a visually pleasing and well-lit shelving system.

The compact high-pressure laminate (CHPL) materials used for this project was Max On Top Avola and Fenix white matching core. The solid surfacing was Staron bright white supplied by Salvocorp.

The CHPL fabrication processes started with creating a design in 3D. These drawings are sent to our CNC operator who loads the drawings for the CNC machine to cut the shapes and self-mounting points. The edges of the cut-outs were sanded to give a clean finish. Whereas, the solid surfacing material was placed in the thermoforming oven to become more flexible in order to be moulded into the desired shelving shape. The solid surfacing shelves are then sanded for a smooth and bright finish.

Once fabrication was complete, our installation team mounted the CHPL cladding pieces onto vertical spaces, which allow airflow behind the CNC-cut material. Our team places stainless steel rods into the CHPL in order to support the curved solid surfacing shelves. We finished off the shelving system with LED lighting underneath each shelf to bring the structure to life.

Wall Mount Phone Stand

Our boardroom’s phone stand was conceptualised to minimise distractions caused by mobile phones during meetings. This playful design is the epitome of Infin8 Surfacing’s out the box thinking, while encouraging focus and attentiveness. The design also proves the flexibility of both products as well as their suitability for all wall cladding applications. The materials used were Max On Top’s Fenix Black and Salvocorp’s Perago Classic White.

The fabrication of the compact laminates was similar to the sample storage process. The solid surfacing sheet was again heated in the thermoforming oven before being places on a mould to give the final shape of the curved stand. The solid surfacing profile was marked onto the CHPL sheet.

The exact profile was then cut out of the sheet to allow the curved solid surfacing element to slot into the Fenix material. The plaque at the top of the curves was CNC-cut and filled with resin to reveal the text and icon 8 symbol.

External Way Finder

Infin8 Surfacing needed a solution to guide deliveries and clients to the correct entry points. Our solution? External wall cladding! We used Salvocorp‘s Staron Bright White solid surfacing material due to the durability of the product.

The solid surfacing was cut using the CNC machine in order to shape the relevant letters and icons. These letters and shapes are then filled with a different colour resin to outline the text. It is then sanded accordingly to leave a smooth and flush finish. The material is joined seamlessly and mounted onto the outdoor pillar using an adhesive.